What do Blue Bunny® ice cream and SmithCo Side Dump Trailers have in common?

They’re both made in Le Mars, Iowa – but you’re probably more familiar with the ice cream brand than with SmithCo.

Located outside the Sioux City metro area, Le Mars was designated the Ice Cream Capital of the World in 1994. The small town, population 10,571 at the 2020 census, is home to Wells Enterprises, Inc., the makers of Blue Bunny ice cream and dairy products.

In the same year Le Mars received its ice-cream designation, a man named Greg Smith founded SmithCo, and with three employees, began building side dump trailers in order to solve an industry problem. Today, the company is the largest manufacturer of side dumps in North America.

Solving a safety problem associated with traditional end dump trailers

You’re most likely familiar with dump trucks (or trailers, as they’re officially called) and how they work. The cab driver operates the mechanism that lifts the front of the tub high in the air — allowing the contents to slide out at the bottom end.

The problem with end dump trailers, however, is that they’re a huge safety hazard being that they’re prone to tipping over.

This was the challenge Greg Smith wanted to solve. After modifying a side dump trailer he found in Oregon, he began using it — and others in the industry took notice.

Greg Smith retired in 2019 after selling SmithCo to Christensen Farms, a Minnesota-based pork producer looking for a larger investment portfolio. His successor is Scott Lovell, President and CEO. Scott started in 2000 as HR manager, then moved to plant manager in 2008.

Proving side dumps work: Overcoming legacy thinking

When asked what obstacles Greg Smith encountered in the start-up days, Scott responded, “legacy thinking.”

“Greg had to prove to people that side dumps were a viable option. End dumps had been around since Moses — everyone knew how they worked. But because it was the only way, everyone assumed they had to accept the risks involved. Greg thought otherwise.”

Because end dump trailers often traverse rocky and uneven ground, they become unstable when dumping and are prone to tipping over. Side dumps, on the other hand, are much more stable.

To prove side dumps worked, Greg crisscrossed the country with his trailer giving demos. People reacted with disbelief when he showed the trailer in operation — but within five years, SmithCo had grown considerably, with production increasing from three trailers in 1994 to 250 trailers in 1999.

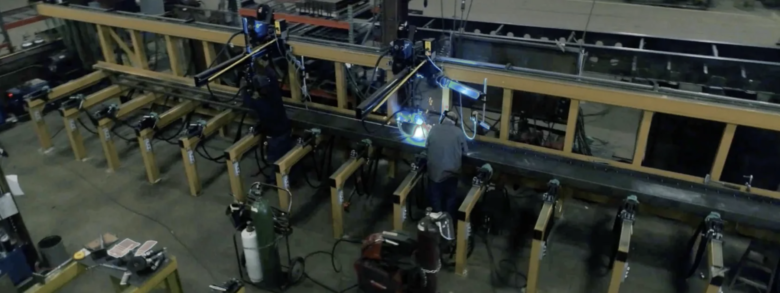

It was at this point that Greg moved the company into its current 70,000 square foot facility — which today consists of state-of-the-art manufacturing processes.

SmithCo continued to grow and now is North America’s largest manufacturer of side dump trailers. The company employs 128 employees and, at full capacity, can produce up to 1,000 trailers a year.

Manufacturing production on the large scale

For the dump body and frame, the company sources steel sheets, which are put on a computerized plasma cutting table where they’re cut, and then formed and welded. Tub and frame welds are inspected multiple times before they’re painted.

The entire trailer is built right on the premise; start to finish time is approximately three weeks. During final inspection, each trailer is operated by technicians to ensure each part works properly — from dumping the tubs to operating the lights.

“We buy the components we can’t make in-house,” says Scott. “Axles and suspensions, tires, wheels, lights, hoses, hydraulics — these all come from various US suppliers.”

“We do source steel from US vendors as much as possible, but we use material from Canada and Finland as well,” he says. “Right now, the steel market is crazy. We’re selling trailers six months out without knowing how volatile steel prices might be.”

The company sells its trailers through a dealer network and has shipped finished units to Guam and the UAE. “The problem with shipping Internationally is that we can’t put a trailer in a container, and you can’t stack them, so getting them on a ship is a challenge.”

Sums up Scott, “SmithCo was founded on an idea of creating a side dump trailer that was fast and stable. Greg Smith achieved that goal — and our entire team works every day to improve on it. When you buy one of our trailers, you’re getting the best, safest, and highest quality side dump money can buy.”

If you’re ever near Sioux City, make a side trip to Le Mars — both for the ice-cream and for a pass-by of SmithCo’s lot where finished trailers are on display. Until then, you can watch the company video, which shows their production process and the side dumps in action. Very cool!

Or, visit the website at: https://sidedump.com/

And with that, I’m going to eat a Blue Bunny Vanilla Mini Swirl ice-cream cone dipped in chocolate. I found a box at the market. Yummy!

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.