With so much discussion about how American manufacturers can compete in this age of lower paid overseas labor, one manufacturer is making a strong case for Made in America — literally!

The manufacturer is PFC: The Plastic Forming Company. It’s been making hard-sided, double-walled protective carrying cases since 1969.

Recently, I was thrilled, after reaching out to Jacquie Gilmore, Business Development Specialist, to have her and Gary Amatrudo, VP of Customer and Product Development, give me a tour of the company’s facility in Woodbridge, Connecticut.

I came away with exciting insights into how this business not only survives, but thrives!, in today’s competitive market — all while producing its products in the USA.

PFC: The Plastic Forming Company

Peter T. Shurmann founded PFC in 1966. An entrepreneur and inventor, he came up with the idea of creating double-walled carrying cases using a double-wall blow-molded process.

Today, PFC has two facilities: A corporate headquarters and manufacturing facility in Connecticut and a Midwest office and manufacturing facility in Ohio. Approximately 25 people work in each facility, with the bulk of manufacturing done in Ohio.

Interestingly, the employees have owned a significant portion of the company since 1989. As they like to say, “No matter who you speak with, you’re talking to one of the owners.”

The Products

Double-walled blow-molded cases are perfect for carrying, protecting and organizing valuable equipment, such as power tools, portable test instruments, medical instruments and educational kits.

For example, here’s a power drill and parts in a PFC case:

The cases are available in a variety of stock sizes, and the interiors are custom designed depending how they’ll be used:

Today, the company has expanded its product line to include more value add-ons, such as customized precision-cut foam interiors and case labels.

Companies such as Snap-on and Olympus use PFC cases to carry and protect their high-end tools and equipment. PFC also receives many special orders, such as cases for storing and protecting fifth wheel trailer hitches.

The Manufacturing Process

Blow molding is the process of melting plastic pellets to form a hollow tube. The tube is then placed into a mold and inflated with compressed air to form a completed part. This process is commonly used to create plastic bottles, for example.

The double-wall blow-mold process is unique because it creates a part with a hollow interior. By combining two of these parts, PFC creates its double-walled blow-molded carrying cases.

With the double-wall blow-mold method, the molded interior of each case is an integral part of the end product. It’s not a separate insert that’s snapped or glued in. As a result, the case provides superior protection and durability.

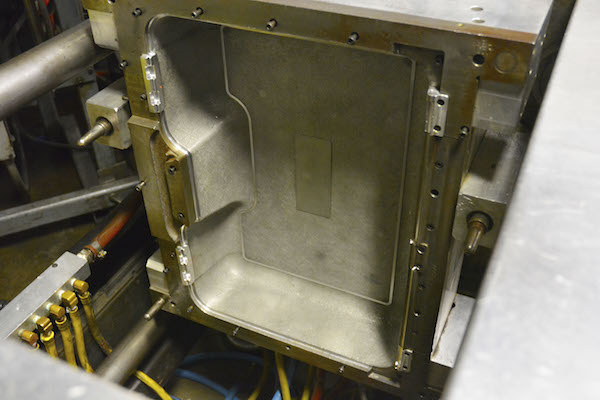

The first step in the manufacturing process is to create a mold for the custom interior:

An existing mold is used for the exterior case:

Plastic pellets are then put into a hopper, melted and injected into the molds:

Case tops and bottoms are created separately and then assembled by a worker in just a few seconds. Generally, it takes only one and a half minutes to make a completed case.

The workers assembling the cases made it look super easy. But, said Amatrudo, “it takes real skill to do what they’re doing – and as fast. Occasionally one of us in the office will try it – it’s much harder than it looks!”

In addition to custom molded interiors, the company also makes custom foam inserts that are precision cut and then inserted by hand. The foam pieces are cut with the aid of a computer-guided precision blade and accompanying CAD file.

Turnaround from order to shipping date is about three to four weeks.

All of PFC’s processes — design, mold engineering and manufacturing — are completed here in the U.S. The company sources 95% of its materials domestically and doesn’t outsource to foreign manufacturers.

The Secret of PFC’s Success

So how has this company managed to thrive in the face of stiff competition? From my research and tour, I can identify three main defining factors:

1. Create a high-quality product at a competitive price

PFC delivers a high-quality case. All of its molded interior cases are made of high-density polyethylene (HDPE), which is resistant to solvents and oils, and can withstand high impacts. The color is integrated into the plastic pellets, so it never chips or wears off. The cases also use hard-wearing mechanical hinges and latches.

At the same time, PFC keeps its prices competitive by combining its standard mold tooling with components for specific needs. This means you can get a PFC case for much less than building a fully custom case from scratch.

2. Maintain high-quality control

Quality control is built into every part of the company’s processes.

Particularly important is visual inspection by frontline workers. According to Amatrudo, they can immediately tell if the plastic is becoming too soft or too hard. They also weigh each case to make sure it falls within certain parameters. If it doesn’t, they remake the case.

Because employees are also owners, they’re highly motivated to find production errors and correct them before the final product is shipped. This helps reduce costs and maintain high levels of customer satisfaction.

The company’s commitment to quality control also extends to system redundancy. The fact that they have two locations in two separate states is no accident. If one factory is taken offline for some reason, the other factory can pick up the slack.

3. Respond to the market with value-add innovations

Both Amatrudo and Gilmore discussed how PFC has sought to keep value-add innovations in-house, instead of reaching to exterior suppliers (and losing potential revenue sources).

The company’s custom cut foam interiors and custom printed labels were both innovations that the company chose to keep in-house.

The company has also responded to the market by adding additional customization options, such as special colors, cut outs, pockets (to store literature) and stacking interlocks.

To learn more about PFC, take a look at the company’s website. You can also see the company’s (tongue-in-cheek) testing of its specialized AllConditions line of cases on its YouTube channel.