After reading Deskbound: Standing Up to a Sitting World in 2021, I purchased a Made in USA iMovR standing desk. The difference was immediate: I felt better and had more energy while working.

The desk came with an anti-fatigue mat, which worked well. But then I got Rocky, my dog, and the constant stress of walking, playing, and standing all day began to take its toll. In the last year or so, my legs, knees, and hips began to hurt. A lot.

I found myself constantly moving the anti-fatigue mat to find a place on it that felt good. I finally removed it and went back to sitting — which introduced shoulder and neck pain.

Along the same time, I discovered Rich Ward, Marketing Director for AcroMat, via a webinar he presented on how his company uses LinkedIn to grow the business. We connected, and I began reading his posts and watching videos (all very well done!) about how AcroMat designs and manufactures custom-sized mats for industrial facilities. I asked if he would be open to an interview for this blog.

While interviewing him, I realized that while my anti-fatigue mat wasn’t “industrial,” it did serve the same purpose: to make standing for long hours much more comfortable and pain-free. So, I shared my story about my mat and how painful it had become to stand at my desk.

“Your mat has worn out,” he said. “We actually send free mat samples to prospects. Would you like one?”

“Oh yes, please!” The company has a special way of packing and shipping their mats, so I was eager to experience the unboxing, plus I wanted to gain an appreciation for the material and see and feel for myself why the company is rapidly growing.

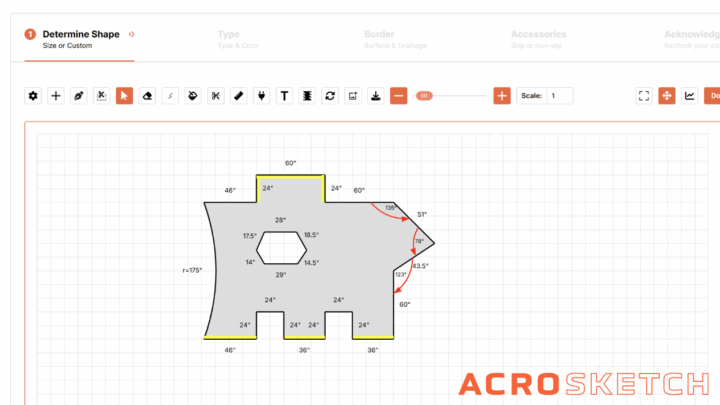

Founded in 2005 and led by Russell Herbert for the past 17 years, AcroMat has differentiated itself in two ways: It’s the only mat manufacturer to make custom-sized and configured mats for industrial applications. Second, the company has developed a tool, AcroSketch, that lets people design their mats to any shape and size online. Both have been game changers.

From start-up to market differentiator in less than 20 years

Just out of high school in the early 2000s, Herbert began selling janitorial supplies in Nebraska. While visiting customers in the industrial space, he often heard they needed anti-fatigue mats custom-made to fit the complex layouts found in manufacturing facilities.

The only solutions available were standard-sized, rectangular mats — which workers, plant managers, etc. would then piece together. The problem: These pieced-together mats created gaps, overlapping borders, and on/off stepping — which led to tripping accidents and ergonomic issues.

“I was very green when I began selling supplies,” says Herbert, “and wanting to learn, I talked to many safety, production, and manufacturing leaders to understand what was most important to them. The issue of mats came up repeatedly.

“No one was making custom-mats — a clear gap in the industry — so I set out to do exactly that. When a company asked for a custom size / configuration, I said ‘Yes’ and then figured out how to build it.”

By “custom-sized and designed mats,” this means the mat is one piece of rubber foam that’s been molded, designed, and precision-cut to fit a complex layout and the machines and other items in it. (Think of a vinyl floor in a kitchen or bath that’s been cut to fit around the cabinets, appliances, door trim, etc.)

As word grew, so did Herbert’s business. In 2017, he moved from Nebraska to the Minneapolis Metro area. Herbert rented a small corner of a facility where he did all the selling and mat production.

Because AcroMat was the only company in the space making custom mats, the company’s reputation began to grow.

The difference: Molded nitrile foam

According to Ward, most anti-fatigue mats on the market are extruded using PVC foam or a blend of PVC foam and nitrile.

Extruding rubber is the easiest (and less costly) way to make foam mats, and why so many mat companies sell them. However, to extrude rubber, you have to add a percentage of PVC foam.

PVC foam isn’t impervious to liquids or chemicals, which can lead to common mat issues such as bloating, cracking, and curling borders. It also sinks or compresses over time, leading to ergonomic inconsistencies, including joint and muscle pain.

AcroMat anti-fatigue mats are molded – versus extruded – from closed cell, 100% nitrile rubber foam. This material is completely impervious to liquids and chemicals, which helps to prevent issues such as absorption, bloating and curling.

This material, combined with AcroMat’s design and construction process, allows the company to guarantee and warranty that its mats will not curl, sink, flatten or compress, or come apart at the seams.

Made in Lakeville, Minnesota

The 20-person AcroMat team oversees all aspects of mat design, production, and shipping from the company’s Lakeville, Minnesota facility – about 20 minutes south of the Minneapolis Metro.

Says Ward, “We’re not a rubber molder, so we source our material, but everything else is completed right here: design, precision-cutting, bonding, assembly, and packaging. All mats are shipped directly from our facility.”

“We also fully developed AcroSketch here in-house, have an in-house printer that allows us to provide custom safety message on any mat, and do all of the manufacturing for Grip-R Non-Slip Coating, which is a bonding we apply to our mats to prevent sliding.”

AcroMat changes the game — again

Designing custom mats can be time-consuming and complicated; AcroMat previously didn’t have an easy way to design and quote custom mat projects. Custom mats clearly solved a real problem, but unless the process was fast and easy for those in need of anti-fatigue mats, it wouldn’t be sustainable or scalable.

Says Ward, “About 10 years ago, Russell had a lightbulb moment after visiting a client facility. He realized we needed to create a way for our clients to design, build, quote, and order a mat to any size, shape or dimension — on their own.”

This insight led to the creation of AcroMat’s proprietary, in-house, custom mat building tool, AcroSketch. Released in 2017, Ward says it’s the only tool of its kind in the industry.

Herbert created the original concept and then worked with a team of developers to bring it to life. AcroSketch allows users to easily design the custom mat(s) they need, see immediate pricing, download a quote — as well as purchase online.

The AcroSketch tool has changed the business. Custom mat design and quoting used to take AcroMat days – and still takes other providers weeks – but now they can design and quote custom mat projects for customers in minutes.

“Safety doesn’t wait,” says Herbert. “AcroSketch has made it so our customers and their standing workers never have to wait either. It’s also halved our lead time.”

While half of all orders are for custom shapes and sizes, it’s a 60-40 mix between the AcroMat design team using AcroSketch and customers using it themselves.

Says Ward, “AcroSketch is an entirely new tool in our industry and not something people have seen before, so we’re still building awareness and teaching our clients how to use it, including creating a How-to AcroSketch library of videos.”

Continued growth — including the physical plant

In the last 15 years, AcroMat has grown from working primarily with clients in Minnesota, and serving them directly from a small room in the corner of someone else’s facility, to taking over a 25,000 sq. ft. facility just down the road.

The building houses the business office and production facility, and has gone through several renovations to allow for expansion and higher capacity.

The company now creates custom mats for some of the world’s top brands across the U.S. According to Ward, revenue has grown over 50% each of the past three years, with even larger growth anticipated over the next three years.

Sums up Ward, “We’ve come a long way from Russell’s rented space in someone else’s facility. Due to AcroSketch, our Lean-optimized production processes, and automated packaging system, we can guarantee a 10-day lead time whether a customer orders five mats or 500.

“Just last year for example, we manufactured, packaged and shipped a single order for a Fortune 500 retailer — over 11,000 square feet and 7,000 pounds of custom-designed mats, including 1.3 miles of ADA-Compliant yellow borders — in one week. This type of order and fast production is now a common occurrence.”

To learn more about AcroMat, visit acromat.com.

Post-Script

My mat arrived, nicely rolled in a box. I could see / feel the difference immediately with regard to material thickness.

Once unboxed, I reconfigured my desk back to standing mode, promptly stood on the mat (which is textured and feels good on my feet), and worked pain-free.

According to Rich Ward, “our mats are made for “long-term standing — 6-8-10+ hours every shift — so they are slightly firmer than a lot of mats out there. The idea is, if you’re going to stand for long hours on a mat, and move back and forth across your workspace, you need to be able to move without sinking, which could be a trip hazard and also puts added pressure on your joints.”

He adds that for those using an AcroMat anti-fatigue mat at home or in the office, you may feel a difference when standing in socks versus shoes; it feels softer in socks, and firmer in shoes, which is by design.

The mat I have is from the QS-100-1 Series, textured with beveled edge, 5/8″ thick, size 2’x3′.

Note: In keeping with my policy to not accept free stuff — even though the company sends free samples upon request to prospective customers, I sent AcroMat a check for the mat. I’m not a customer, but I am now a huge fan!

Plus, the shipment included a packet of gummy bears — which I promptly ate. Nice touch!

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.

Links

Richard Ward, LinkedIn — Follow Rich for lots of informative videos and posts

Made in USA: iMovR Standing Desk — A Keep It Made USA write up

Full Disclosure

I’m not paid nor asked to write about products or the companies that make them. All links in this piece are FREE — meaning, they’re not sponsored or paid for.

My mission is to keep manufacturing jobs stateside and this blog is my way of giving back. We like to think a “small” choice, such as purchasing something made in the US, won’t make a difference. It does.