“We sold our first Woodhaven firewood rack over the Internet in 1998,” says Jeff Alexander, Brand and Product Manager for Alexander Manufacturing. “The process was so new, it totally freaked us out!”

In the early 1990s, Jeff’s dad Don Alexander realized the availability of high-quality firewood racks was next to non-existent. Don developed a solid design but had a very hard time marketing it.

“The big box stores weren’t interested,” Jeff says. “They were only looking for price and not quality.”

The company did attend a wholesale trade show where they began meeting with specialty fireplace dealers, which helped them build a network.

It was the Internet, however, that really got things moving.

“This was the early days of e-commerce,” says Jeff. “We were one of the first companies to have a website. We had to send the hosting company in South Africa our corporate papers just to get a secure site. Getting that first order was wild!”

Woodhaven Firewood Racks – made in Parsons, KS

Alexander Manufacturing is both a contract manufacturer and a direct-to-consumer product manufacturer.

Don Alexander and his sons were able to create the Woodhaven Firewood Rack because they made machines for manufacturers — and thus had the equipment and the expertise.

In the early days, the company manufactured the racks in their old machine shop, and then sent them out to be powder coated. Over the years, they’ve streamlined operations, including adding a robotic welder and an in-house powder coating line.

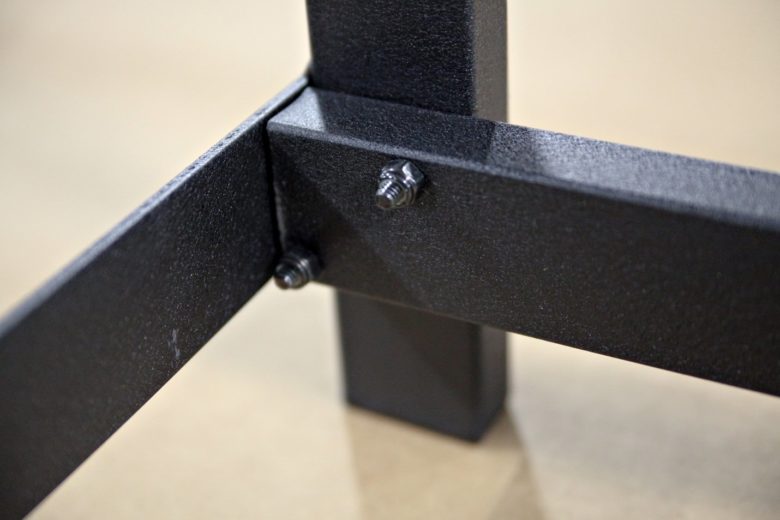

Today, the racks are made of durable 16-gauge structural steel. A welded frame, with precision drilled holes and stainless-steel nuts and bolts, ensure structural integrity once the rack is built. The racks are then powder coated and ready for shipment in a compact package and are easily assembled with a wrench.

“Our main problem was getting the word out,” says Jeff. Located in the southeast corner of Kansas in Parsons, the company isn’t near its customers, who tend to be located in the Northeast and Northwest — places where firewood is used to offset home heating costs in winter.

After attending the wholesale trade show for 20 years (with an annual cost of $30K – $40K), Jeff and the marketing team made the decision to stop attending because their main audience, representatives from specialty stores, and were no longer going to shows; instead, they were finding the company and its products online.

Since then, Jeff and his team have forged relationships with firewood and fireplace dealers through social media (Instagram and Facebook). Woodhaven products can be purchased online directly from the Woodhaven website (link below) or from select retail dealers and on Amazon.

The company continues to innovate by listening to customers’ ideas.

“Some ideas aren’t cost-effective,” says Jeff, “but they help us devise a different solution.” For example, customers ask what they could put under the rack feet to prevent scratching of a deck or porch or to provide a barrier to damp soil.

“We knew we couldn’t ship paver stones, so we designed our Rack Support Base. It’s made of heavy duty, injection-molded ABS plastic — and it became an instant hit. We thought they might do well, but not as well as they’re doing. It’s really about listening to consumers and finding solutions!”

In addition, the company is moving into fire pits and also offers fire starters, log carriers and other items. Their goal is to offer complete product lines.

Fireplace tools, on the other hand, are more problematic. Because they’re used in people’s interiors, consumers are much more choosey and want a range of design styles.

“We also ran into problems with the brushes because they can’t stand up to hot coals,” says Jeff. For now, the company has deferred adding fireplace tools to their product line.

Bred in the bone: a love for inventing

A woodworker, Melvin Alexander founded Alexander Manufacturing in 1927. At the time, he made little toy bow and arrows that he sold to F.W. Woolworth Company (aka Woolworth’s), as well as wood parts for Ford Model T frames.

Between WWI and WWII, he transferred to metal and founded a metal foundry, where he also developed ammunition and firearms. In fact, he tested and solved challenges involving bullets for the United States Army — developing a bullet that increased velocity when it left the firearm.

According to Jeff, the family found top secret drawings — which listed the U.S. Secretary of State’s name and phone number! — in Melvin’s papers after his death. Melvin also oversaw the development of a machine that produced 50mm shells, as well as parts for military equipment. After the war, that part of the business was no longer needed for the war effort.

Melvin’s son Dale purchased the company in 1964, making electric winches, custom machinery, and running a machine/welding shop until his retirement in 1989. Today, the company is owned and operated by Dale’s son, Don Alexander, his wife Jane, and their sons Jeff and Joey. Various cousins, aunts and uncles work in the factory as well.

The tinkering and inventing continues. “It was the machine-making for our customers, and the continual tinkering, that led to the firewood rack,” says Jeff.

Customers appreciate Made in USA

Jeff says the company receives feedback almost daily from customers, including Amazon reviews. “One customer left a minute-long voice mail that was really nice.” Another customer emailed to say his dog ate his rack’s plastic end caps; the company sent him replacement caps, no charge.

The management team shares the reviews with employees who make the racks. “We want them to understand that what they do matters,” he says.

The one component they do have trouble sourcing in the United States is the rack cover, which is a made from a PVC fabric and machine-sewn. “We need a company who can make these efficiently for us!” he says. “Be sure to state we’re looking for a US textile contract manufacturer!”

I own two Woodhaven Firewood Racks and LOVE them. (I bought the second one after using the first one for a year.) They’re incredibly easy to assemble; I love how sturdy and handsome they are, and that I no longer have to worry about my stack of wood falling down when I remove that one log holding everything together. I’m also thrilled they’re made of US-sourced 16-gauge steel and powder-coated.

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.

Links

To learn more about Alexander Manufacturing and their contract manufacturing services, visit: https://alexandermfg.com

To learn more about the Woodhaven Firewood Rack and associated product lines, visit: https://firewoodracks.com

Full Disclosure

I’m not paid nor asked to write about products or the companies that make them. All links in this piece are FREE — meaning, they’re not sponsored or paid for. I buy products, use them, and if I like them, I tell everyone about them.

I do this because my mission is to keep manufacturing jobs stateside. This mission is my way of giving back. We like to think our “small” choices won’t make a difference. They do.