My mission with this blog is to help people become aware of the importance of buying Made in USA products. My long-term vision, however, is to tell the stories of companies that no longer exist. It’s important their history isn’t lost and that we remember manufacturing is much more than production and machines — it’s about people.

This is the story of C.J. Bates / Susan Bates, Inc., manufacturers of Susan Bates crochet hooks and knitting needles.

In its heyday, the Bates factory in Chester, CT produced over 100,000 knitting needles and crochet hooks a day under the Susan Bates brand. A person who knitted or crocheted (or both) would own all sizes or gauges of needles and hooks.

I personally own 20 Susan Bates crochet hooks, which until recently had been sitting in a box down cellar for over 20 years. I began crocheting as a teen; by the time I was in my late 20s, I was crocheting intricate patterns – and would often gift these items to friends and family.

When I retrieved my hooks from my dust covered crafts box earlier this year, I immediately noticed the “Made in USA” stamped into them. After some searching, I learned the Bates company was no longer in business.

Intrigued, I ended up driving to Chester, a small town nestled by the side of the Connecticut River, to view the buildings where my crochet hooks had been manufactured.

During my visit, I met Cary Hull, Director of the Historical Society. She gave me an impromptu tour and a copy of the Chester Scrapbook.

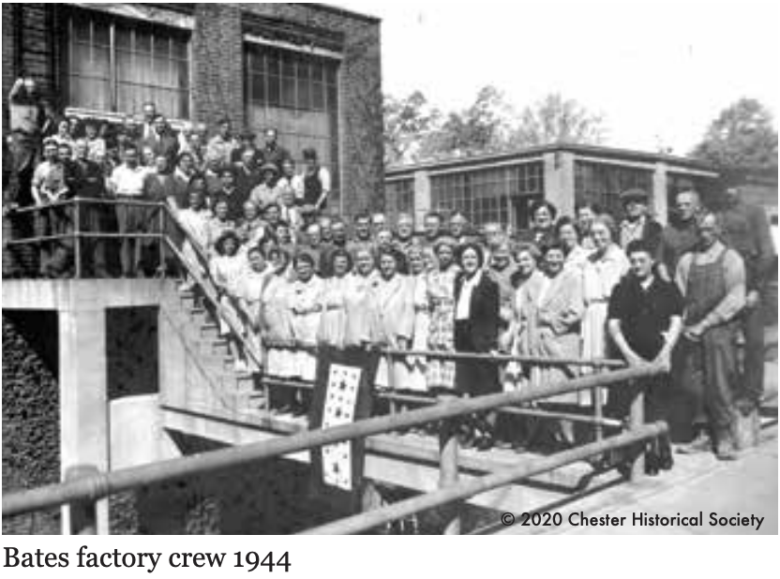

I made the visit because the Bates company had employed 75 people and was the town’s largest tax payer.

As a made in USA advocate, I wanted to get a sense of what happens when a technology and manufacturing plant leave a small town like Chester. Mostly, I wanted to tell the story of a company that’s a forgotten footnote in the annuals of US manufacturing.

Chester, CT: Manufacturing and industry bred in the bone

Located north of Old Saybrook, Chester’s first industry began in 1680, when men sailed up the river to cut and then export shingles and clapboards from the cedar trees that grew in abundance.

Once the town was settled in 1692, its bustling industry grew to include shipbuilding, grist mills, tanning, and iron foundries. Winding through Chester are the North and South branches of the Pattaconk River – along which were located several industrial buildings, including one owned by brothers Daniel and Joseph Silliman.

The brothers manufactured wooden goods, including portable inkwells, which Union soldiers carried with them to the Civil War. Fountain pens replaced ink wells and the Silliman brothers died; the Silliman factory was purchased by Carlton J. Bates in 1873.

C.J. Bates – Largest manufacturer of crochet hooks in the US

Carlton Bates produced articles from bone, including crochet hooks, and expanded his line to include steel manicure implements. After his son Horace joined him, the business expanded yet again – and the Bates company moved into a larger but old factory complex, which had been owned by another Silliman family member.

The firm officially became C.J. Bates in 1907 and began expanding its needlework tool line by introducing wooden crochet hooks and knitting needles. Plastic and aluminum crochet hooks made their way into production in the 1930s – but manufacturing was paused during WWII as the factory was converted to produce parts for the war effort.

The company replaced the old wooden factory buildings with a modern brick factory in 1940. Carlton Bates remained active in the business until his death in 1941.

The company incorporated in 1960; in 1970 it moved to a more modern and larger building across from Town Hall. The name was changed to Susan Bates, Inc.

According to an internal Bates document I found at the Lace Buttons blog, by 1971 Bates was the oldest and the largest operating crochet hook manufacturer in the United States. Fifty people made and packaged over 100,000 hooks and knitting needles a day!

The company also received several patents and awards. “In 1944 Bates received a patent for the in-line hook shape. In 1952 a patent was issued for the Clips-on thread retaining clip. The 1960s saw changes in mass marketing and Bates received several awards for packaging and display including awards for color coded crochet hooks and point of purchase displays,” reads the internal document.

A tradition and a history reduced to a “brand”

In 1976, the family-owned company was purchased by Coats & Clark – which itself was purchased by Coats in 1986. Coats moved all production to Greenville, South Carolina in 1992. The seventy-five people who worked at the factory lost their jobs – many of whom had worked there 20, 30, and 40 years.

“Closing the factory is still a sore point with some people in town,” said Cary Hull.

The Susan Bates brand was absorbed into numerous Coats brands. Coats spun off the Coats & Clark brands in 2019. Today, the Coats & Clark brand (thread), along with Red Hart (yarn) and Susan Bates, are owned by Spinrite, headquartered in Canada.

I emailed Spinrite and learned Susan Bates hooks and knitting needles are manufactured in China, Malaysia and India. (Yarn is outsourced as well, although sewing thread is spooled in North American mills.)

Reading online forums and posts by crafters, it’s easy to see that Susan Bates crochet hooks still have a loyal following, but few people know the history behind them or where they’re now made – or that they were once made by people in a small New England community.

All I could hear were ghosts

Walking the downtown of Chester is like stepping back into a quaint New England village. I enjoyed lunch at a local café with tables set outside and wide plank wooden floors inside. I sat at a window table, with the late winter sun streaming in, and watched families, friends, and tourists come and go.

It was short walk from the downtown to the 1940 Bates factory building on Goose Hill Road; the factory is now a theater. (The company donated it to the Goodspeed Opera House of East Haddam.)

The building has been modified to suit the theater, but even with the modification, it’s still a wonderful example of an old mill.

It was so quiet, I could hear ghosts. While taking photos, I met an older couple out walking. The gentleman said his grandmother and grandfather both worked at the factory and that he would run down from school in first grade and visit his grandfather, who worked in one of the first-floor offices and oversaw anodizing. His grandmother did knitting needle assembly.

I could see him as a young boy, running down the hill, happy to be done with school for the day and eager to visit his grandparents at work – and perhaps share a cookie during their afternoon break.

Our shared manufacturing history: It’s all about people

I’ve thought a great deal about what happened to the Susan Bates Co. It’s the prerogative of business owners to sell their companies – to fund retirement dreams and/or leave a financial legacy to succeeding generations.

So, I can’t fault the Bates family for selling to Coats & Clark, who did keep manufacturing in Chester until they themselves were bought by Coats.

But, I can’t stop thinking about the 75 people who lost their jobs, and the businesses that relied on Bates for their livelihoods – companies such as Durable Wire, which was located in Branford, CT and supplied Bates with the wire used to make the hooks and needles.

And it’s disheartening to know a patented technology – in this case something simple and beautiful in the form of a crochet hook – was developed by American ingenuity but is no longer manufactured here.

The one thing I’ve come to learn buying Made in the USA products, is that you can often feel the pride and craftsmanship of the people who put their lives and souls into the company – and doing a job well.

These items possess an energy all their own . . . and it’s this energy that makes them a pleasure to use, touch, and display.

It’s even better when you know the story and the people behind these products. You form a connection.

I also understand technology has to advance – and that change is a constant. Fountain pens replaced inkwells, email has replaced hand-written notes.

But damn it, couldn’t we have found a way to keep crochet hook and knitting needle manufacturing here in the US?

Perhaps by sharing this story of Susan Bates, a company that positively impacted crafters’ lives for generations, a business owner reading it will reconsider selling his or her company, and work instead to keep the technology – and most important, the people – in place. (An ESOP is one viable alternative.)

It’s so important that we do, for our national and our own personal well-being.

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.

Visiting Chester, CT

If you’re in New England, take a weekend and visit this charming town (and other towns along the Connecticut River). Chester is also home to the Chester / Hadlyme Ferry, one of the last remaining ferry services in CT. Check the town website for details.

While my visit was only for a day, I kept thinking, “This would be a wonderful place to live when I retire.” I loved poking around and reading the historical plaques. By visiting, you’ll get a wonderful sense of New England’s manufacturing and industrial history.

While you’re there, visit the Historical Society and say hello to Cary Hull for me.

Carrie

My grandfather was a salesman for CJ Bates. He traveled and then worked from the factory before his retirement in the 60’s. I have manicure sets, knitting needles and nail files made by them.

Dianna Huff

Hi Carrie — Thank you for stopping by and for adding to the story. How long was your grandfather a salesman? Did he grow up in Chester?

The Historical Society has a manicure set in their Bates display.

Matilda Yenowich Dumbrill

My first job after baby sitting…under age, paying my first Social Security amount of a few pennines…pretty inflated by this time, I hope!

My job: stretching fine suede over the buffer item that went into the manicure whatevers…

I spent a lot of time looking around at this real working world until Stuart Joslyn.who had hired me, reminded me that I had a job to do!

Dianna Huff

Matilda — ha! Great story and what a good first job. 😀

Connie Bates Feola

When the company was sold (and it was to fund the owners retirement), there was a guarantee made by the Coats operation to keep it in the town of Chester for a certain period of years in order to keep the jobs in town. I believe it was actually sold in 1976.

Dianna Huff

Thank you for adding to the story, Connie. It is to Coats’ credit they kept the jobs in Chester for as many years as they did.

Laura

I just found this article by happenstance while searching for information on Susan Bates Silkon crochet hooks. The Silkon line was before the Quicksilvers and are the smoothest crochet hooks that exist on this planet and will probably never be duplicated. I cannot fathom why the Silkon line was ever discontinued but that was probably the biggest mistake ever made in the crochet hook industry. Your article is very informative and well researched and I thank you for putting it out here.

Dianna Huff

Laura — I hadn’t heard of the Silkon line – thank you for the information. I’m glad you enjoyed the article.

Melissa Prime

I inherited a bunch of needles both knitting and crocheting. A couple of them have the original packaging that say ‘Susan bates’, the size, the cost ($1.25, haha) and the company information. C.J. Bates&Son Inc , since 1873. Decided to look it up and found your article. I will definitely have to go to Chester as I don’t live too far from there 🙂. Thanks for writing this!

Dianna Huff

Melissa — Oh, thank you! Chester is a wonderful little town to visit for the day. Be sure to have lunch at the cafe!

Kim

Did you ever find any information about the Silkon line? I left my beloved needle at my cousin’s house. She mailed it back to me but the needle tore through the envelope and got lost in transit, unfortunately.

Dianna Huff

Hi Kim,

I didn’t research that line, so I don’t know where it was made or when. If you can determine date of manufacture, see if that corresponds to when Bates was in CT — and then contact Cary Hull (cited in the article) at the Historical Society. She may be able to help you.

Betty Okerlund

I was organizing my collection of crochet hooks 2 days ago and came across some bone hooks. Thank you for the article!

Dianna Huff

Betty — My pleasure!

Rebecca Ward

I have my Grandmother’s Tatting Shuttle by Susan Bates. She was born in 1897, so I don’t know when she purchased it, but I cannot ever remember when she was Not using it. I have fond memories of her quick hands moving it through her fingers and producing beautiful items. I tried to learn the skill of tatting from her, but it was just too difficult!! Oh, wonderful memories.

Dianna Huff

Rebecca — what a wonderful memory and thank you for sharing it!

Judy Davis

I have a Susan Bates tatting shuttle from my great aunt. Is there any way to find out what year it was made? I finally learned to tat using videos and books and am finding joy in using her shuttle!

Dianna Huff

Judy — Contact Cary Hull, Director of the Historical Society (mentioned in the article) and see if she can help you. The Society has all kinds of Bates stuff.

Louise Sepulvado

Thank you, Dianna for your article. I enjoyed reading it. I’ve used Susan Bates Crochet Hooks since I learned to Crochet in 1969-70. I’ve used the aluminum ones and I love the Susan Bates Quicksilver Crochet Hooks.

The original Quicksilver crochet hooks had the perfect balance. They didn’t make them for very long. I believe they were a type of aluminum. They’re my favorites. Even when I would try other brands, I always came back to my Susan Bates Quicksilver Hooks. Thanks for the memories. Louise Sepulvado

Dianna Huff

My pleasure, and I’m glad you enjoyed the article.

Brenda Simms

Thank you for sharing your research and knowledge.

Dianna Huff

My pleasure, Rebecca.

Mark

My plant that I worked at in Minnesota closed in 1995. I found similar work in California but that plant closed in 2000. And yes the next plant I worked also closed, in 2003. I’m fortunate to be at my current employer 20 years.

Even though the previous 3 plants found it economically justified to source the work outside the US, our country might be better off hanging on to that manufacturing technology.

Mark

I should add that I heard of Susan Bates knitting needles on YouTube, a video of the What’s My Line TV show, a regional sales manager for the company appeared, 1965.

Dianna Huff

Mark — Yes, I completely agree, which is the main reason I started this blog. Thank you for visiting and your comments.

Rosie Singer

Dear Dianna,

I love the history of Susan Bates, crochet hooks. I am an avid crocheter a skill taught to be by my grandmother when I was just a child. I have her crochet hooks which she gave me when she was no longer able to see to crochet. I’ve looked through my bag of old Susan Bates hooks and only is left that was made in the USA. The others were made in Mexico, which I found very interesting.

Dianna Huff

Hi Rosie — Yes, I have a few Susan Bates hooks that don’t read, “Made in the USA” as well, which is what started me looking at the history of the company!

Mary Baker

Thank you for this description

of Chester and the work

people there did and the town today. Interesting history.

Suzanne Guertin

I just purchased some Barbara Bates Circular Knitting Needles at a yard sale. Could not find any information on line. All I saw were Susan Bates. These were made by C.J. Bates & Son. Chester Connecticut. No date given.

Bonnie

Very interesting. I’ve been using Susan Bates crochet hooks for 50+ years but did not know the history of the company until now. Glad I ran across this article.

Steff

I loved this article! I live not too far from Chester. It is a lovely little town with a rich history. I collect crochet hooks (…and thimbles…and pin cushions…and the list goes on!). Recently, I visited a local consignment shop and found oh, so many Bates hooks, still in their packages, with the Chester address on the package and a proud “Made in U.S.A.” stamp. I don’t plan to open the packages, preferring to keep them intact out of respect for the workers who created them.

Dianna Huff

Steff — Wow!! I’d love to see a photo of the Chester address on the packaging. That’s amazing — and good for you. I wouldn’t open them either.

Thank you for the kind words about my post.

Debbie

found several of these knitting needles and crochet hooks in my husband’s grandmas things. she was an avid crafter and could knit or crochet anything by looking at a picture! I have no idea where they are going from here since I don’t knit and my hands, due to RA, won’t let me crochet.

Dianna Huff

Debbie — Try selling them on eBay. Lots of people would love to have and use them. Great find!

Debbie S.

I recently damaged my vintage crochet H which reads SIZE 8 or H with the made in USA stamp

The other side is blank

I am very upset and I keep looking and buying hooks on EBay but so far I have not found a match

Any advice would be greatly appreciated.

I constantly crochet and have many projects to complete

Thank you.

Debbie

Dianna Huff

Hi Debbie,

Try Etsy. I see lots of Susan Bates hooks for sale there, still in the package. Not sure if they were made in the US, but you can ask.

Kim

I have rheumatoid arthritis as well and I Make a way to still crochet and knit.

although I do not use Susan bates needles (I use boye hooks) I was glad to have found this article

Dianna Huff

Thank you, Kim. I’m glad you’re still able to crochet and knit.

Nan Bloch

I have a knitting kit containing do, straight, circular needles along with stitch markers, crochet hooks, stitch holders, tape measure etc. The items are red, white and blue. All are held in with individual elastic. I am guessing it is from the 1940’s. Does anyone know anything about it? Very willing to sell or donate to a museum.

Dianna Huff

Hi Nan,

Does the kit have a company name anywhere on the packaging or any of the items?

Kimberly Jeican

I’ve been crocheting since I was 10 years old. My mom, grandma and great grandma were all crocheters. I was taught on the old school Susan Bates crochet hooks. I love them. Happy Crocheting!!!

Dianna Huff

Thank you, Kimberly. That’s so wonderful you come from a long line of crocheters!

Tika Jane

What a lovely story, yet quite sad in the end. I’m an avid crocheter and an avid lover of everything “Made in America.” I was actually interested in HOW the aluminum hooks are made, but can’t seem to find anything on the subject. I don’t want to make them, I’m just nosey LoL Anyway, thank you for this history lesson. It was quite fun to read!

P.S. I would have been VERY upset at how it all went down, and I truly hope those people were able to find work!

Dianna Huff

My pleasure! I’m glad you enjoyed the story. As for how they were manufactured, I’m assuming through a process called “wire forming.” Check out Acme Wire Products to learn about the process and what else can be made. https://acmewire.com/ Mary Fitzgerald, the CEO and a colleague, is the one who told me that Durable Wire used to supply the wire used to make the needles and hooks.

Tika Jane

Thank you so much! 💓

Dawn

omg!

I enjoyed your story! I love Susan bates hooks! someone at work recently acquired some knitting needles a gauge and stitch holder.never opened! I crochet and knit so I was given these items.

so surprised to see made in Chester Ct.! I live in Ct and found it interesting. so glad I found your story! I think I will have to take a trip and check out Chester .

Dianna Huff

Hi Dawn — Def. make the trip to Chester. It’s a lovely New England walking town with a ton of history. Glad to hear you were given some Bates items!

Hillary

Wow, thank you so much for all the information. I know how important it is to remember the history of our products before they were bought but larger companies. I found this trying to find out if I was able to buy Susan Bates crochet hooks directly from the manufacturer (from what I can find the answer is no). I truly enjoyed learning everything you wrote. Thank you so much for your time!

Dianna Huff

Thank you, Hillary, for your kind words. They mean a lot and keep me going on doing this type of research.

Vivienne Sheppard

i happen to be using a Susan Bates circular knitting needle, blue, plastic, very comfortable. It’s a US8 which, in England now, I think of as a 5mm. I reckon I’ve had it since the 1970s. Idly, I wondered if C J Bates was still around – and came across your blog.

How interesting if sad that the company’s been sold and manufacturing moved overseas. Perhaps with today’s interruptions to international shipping, manufacturing of many products will be brought back. No sense in saving money on cheaper manufacturing if you can’t get the goods to markets!

Thank you for your research and for sharing it.

Dianna Huff

My pleasure, Vivienne — and thank you for stopping by and sharing your thoughts.

Angela

Hello Dianna,

I am researching the company of Coats & Clark and mainly the production of Susan Bates crochet hooks for a school project. Your research is very well done and I was wondering if you would be willing to share the sources you used for finding out where Susan Bates crochet hooks are now made?

Thank you.

Dianna Huff

Hi Angela,

Spinrite makes the Susan Bates brand hooks and needles, and all I did was email the company to ask where they were made: https://www.spinriteyarns.com/contact-us

A person was nice enough to respond!

Linda

I have a Susan Bates, CJ Bates & Son tatting shuttle. I would have sent a photo but this didn’t give me that option.

Dianna Huff

That’s great, Linda!

George Croft

I was wondering if you were aware of the quality of the Susan Bates crochet hooks that are being sold. The newer ones being sold are somewhat sharp and do not glide through yarn as smoothly. Unless this problem is corrected I’ll just find as many of the ones that were made in the 80’s and 90’s.

Your older crochet hooks can’t be beat.

Thx George

Dianna Huff

Hi George — No, I didn’t know, but it wouldn’t surprise me.

Natasha

Beautiful article. Thank you. As a knitter and a crocheter nerd, I didn’t know about this monumental homestead for knitting/crocheting until now.

Dianna Huff

Thank you, Natasha!

Jan Winkelbauer

I have been using Susan Bates crochet hooks forever. I love the bamboo handled ones. The old crochet hooks have a more rounded and but the new ones have a pointed and to them. I don’t like them is it possible to get some of the old ones still. Please send me information on getting those or where I can get them. Thank you. Jan W.

Dianna Huff

Hi Jan — I don’t sell products; I write about them. I recommend looking on eBay or Etsy.

Bec

I was digging through my stash of crochet hooks, some I picked up at a garage sale and found they were made in the USA and Mexico. The Made in the USA made my finger start a tapping to know more, then I found your article. Thank you for writing it!!! Do you happen to know when they stopped making them in the USA? When they started/stopped making them in Mexico. I would love to try and date my hooks.

Dianna Huff

Hi Bec — Thanks for stopping by! I would guess they stopped US production when the company was purchased by Coats and then moved to South Carolina in 1992.

Linda Blaskowsky

Amazing article! Thank you!

I’m now gifting my crocheting granddaughter w my Grandmother’s

Susan Bates hook, circa 1952.

Happy to have some history💕

Blessings,

Linda in Texas

Dianna Huff

Thank you, Linda! And what a wonderful gift to your granddaughter!

Stacey West

Thank you for sharing your curiosity and for taking the time to follow that up with this interesting piece of american history. I have used the Susan Bates hooks for 40 yrs and they are still my favorite crochet hook of choice and I will think of all those people who gave their time and careful attention to this company and to the products they produced. I love the human side of where and how we came to enjoy these products that we love.

Thank you!

Dianna Huff

My pleasure, Stacey — and thank you for reading my post and leaving a comment.

Jessica Wolk

Thanks for this great blog post! I’m a life-long crocheter and I teach crochet as an elective at my school. It’s a huge loss that these fine crochet hooks are no longer manufactured in the US. The quality has suffered. The tips aren’t as pointy and the finish is not as smooth as it once was. I pick up old ones when I come across them.

Dianna Huff

Jessica,

Thank you for continuing to teach an “old-school” skill. You are amazing! I’m glad you enjoyed learning the history of CJ Bates crochet hooks.

Amma

i love Susan bates. so hard finding the hooks. Now I l know, I’m not alone. 🥲

Dianna Huff

Amma — I feel your pain.

Edna Ford

The beauty of my old Susan bates crochet hooks is so beautiful and they sit in my hand perfectly. I have had to buy the newer ones for my group of women who crochet for our local hospital. I treasure mine that actually say USA

Dianna Huff

That’s wonderful, Edna. I’m glad you have the Made in USA models.

Bob Sheffler

I grew up during the 40’s and 50’s just up the hill on High Street from the C. J. Bates and Company factory (about 500 ft. away) near the corner of High Street and North Main Street. The 1940’s factory is actually on North Main Street. My grandfather was William Russell Watrous who was superintendent of the factory during the 30’s and 40’s. I knew the company had moved to the new location in Chester between the Middlesex Turnpike (the old Rt. 9, now Rt. 154) and the Connecticut River. It appears that that building is now occupied by Greenwald Industries.

At least the old factory building is now preserved by Goodspeed Musicals. The old Goodspeed Opera House by the East Haddam bridge was almost lost in the early sixties. It was being used by the State for storage, and there was talk of tearing it down, but fortunately it was rescued.

Dianna Huff

Bob, Thank you for the bit of history. I did stop at the “new” factory on the Middlesex Turnpike when I visited Chester. That’s wonderful you have family history with the old factory — and yes, I’m glad that building was preserved.

Joyce

I learned to crocchet from my grandmother at age 10 in 1964. She crocheted doilies, table toppers, table runners and even bed spreads with crochet thread. I remember her using those tiny metal hooks she referred to as ‘needles’.

I was on an Amazon Sunday looking to buy a Silvalume set of Susan Bates crochet hooks and bought a set that had the CJ BATES & SON brand. I wondered if they were relatives of Susan; who I always assumed was a real person. I could not stop thinking about it and decided to google them and found your article, and am so glad to know the history of my hooks! The Susan Bates hooks I still own in the plethora of hooks I have now have sentimental value.

Thank you for your article!

Dianna Huff

Joyce — Ah thank you so much. It’s wonderful that your grandmother passed down the love of crocheting to you at a young age. And I’m glad you now know the history of your Susan Bates hooks!

Lynn Gorham

I came across this while looking up why one of my Susan Bates knit-check gauge/needle size tools has Chester Conn. and the other has Greenville South Carolina. thank you for the interesting article! Mystery solved.

Dianna Huff

Wonderful! I’m glad you found it helpful.

Li

What a wonderful article! I am preparing to teach crocheting at the university level (somewhat scary!) and this is so helpful! I was specially excited that Susan bates invented the in line hook!

Dianna Huff

Thank you! And good luck with your class. How exciting!