Porcelain enamel lighting was once the industry standard for exterior lights in the early and mid-20th century. Exposed to the elements 24/7, the high-gloss porcelain enamel fixtures retained their color for years, even under intense sun.

But as new manufacturing processes came into play, including powder coating, the quality of exterior lighting fixtures began to decline. Eventually, as manufacturers off-shored production, porcelain enamel outdoor lighting became a thing of the past.

That is until Bryan Scott turned a hobby into a multi-million dollar business.

A collector of antique fixtures, Bryan and his wife Donna would frequent yard sales, estate sales, and antique stores. Bryan would find vintage light fixtures, including porcelain enamel barn lights, and bring them home for a cleanup and re-wiring.

He and Donna collected so many lights, he set up a simple web page to begin selling their finds.

“I was in law enforcement,” says Bryan, “and my wife was a nurse. We wanted to supplement our income and pay for our hobby. Shortly after 9/11, I was recruited into the Federal Air Marshal Service. I was sitting on a plane for 12 – 14 hours a day. I studied for my Master’s degree and thought, ‘Now what do I do?’”

The “simple” web page, however, was beginning to deliver real sales – especially for the vintage barn lights.

Bryan then began studying marketing, websites, and SEO while on his flights and in February 2008, launched Barn Light Electric.

“The response was crazy!” says Bryan. “We hit a niche no one else had. We learned from customer feedback that no other company was selling this vintage-inspired lighting. People searching for the fixtures found the website. Business just exploded. I’d get on a plane in Orlando, land in Chicago, and find 6 – 8 calls from customers about our lights.”

At first, it made sense for Bryan and Donna to keep their full-time jobs. On his days off, Bryan manufactured fixtures in the barn. But, he had little time to actually run the business.

Donna took a 90-day leave of absence from her job to help – and never returned.

“We launched the business during the worst economic downturn in history,” says Bryan. Despite the recession, the company did $1.2M in business that first year.

They had clearly hit on a real need in the market.

Porcelain enamel vs. powder coating

Because porcelain enamel doesn’t scratch, scorch, discolor or burn, it’s often used on higher-end appliances such as cooking ranges, ovens, and washers and dryers.

Most light fixtures manufactured today feature powder coating. While providing a durable finish, powder coating is a less expensive process than porcelain enamel and offers a more matte finish.

From the beginning, Bryan created his own lighting using the traditional method of shaping the steel metal covers on a lathe and then finishing them with porcelain enamel.

Today, Barn Light Electric is the only company in the United States to manufacture porcelain enamel lighting.

All fixtures made to order

According to Samantha Gumieny, the company’s marketing manager, people immediately see the difference between Barn Light Electric’s fixtures and those from other companies.

“Customers can choose the color, style, shape, and size of their fixture. No other manufacturer offers the level of customization that we do,” she says.

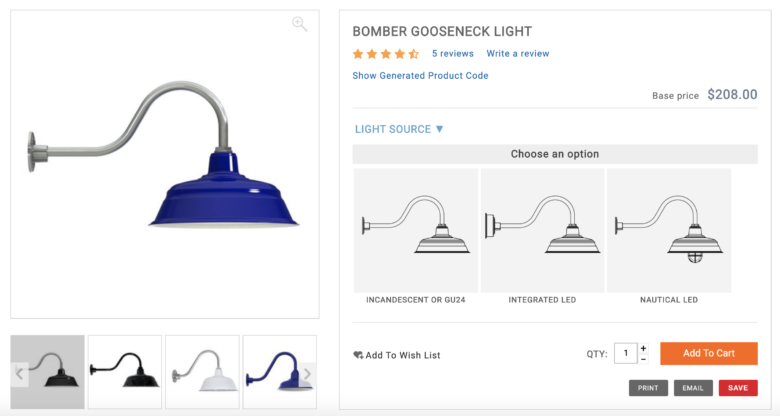

In fact, customers can build their fixture right on the web order form [Figure 1] – beginning with the light source (e.g. LED vs. incandescent), shade size, fixture finish, mounting style (gooseneck arm, cord style or stem length) and even the socket type.

For customers ordering lamp posts, customizations include pole height and finish and glass type (e.g. frosted, clear, ribbed).

“We’re proud to manufacture most products right here in Titusville, FL in our 70,000 square-foot manufacturing facility. Every fixture is built to order,” says Samantha, “with meticulous attention to detail.”

“The people who purchase from us do so for a number of reasons,” she adds. “Many are looking for a product made in the USA. They also want something unique and that they can customize exactly as they’re envisioning.”

The frictionless order form has undergone numerous iterations and continues to be updated based on customer feedback. Says Samantha, “We’ve worked really hard to make the form intuitive and easy-to-use.

In-house Marketing

“In the beginning,” says Bryan, “when I was reading and listening to everything I could find, a business expert on a podcast was asked, ‘What’s the one thing you’d recommend to someone starting a company?’ and he replied, ‘Hire a good copywriter.’”

Bryan took that advice to heart and hired Betty Lynne in 2012. Today she’s Marketing and Media Relations Manager – while also serving as the company’s historian of tribal knowledge.

All marketing is done by an in-house marketing team comprising SEO specialists, graphic designers, photographers, and copywriters. Their job is to build the Barn Light brand through the website, various social media platforms, PR, trade shows, and collateral.

Barn Light Electric today

Since 2008, the company has expanded its manufacturing footprint and is currently in its fifth building – having outgrown the previous four. “We’re about maxed out in our current facility,” says Bryan.

From its humble beginning in the barn, the company now employs 124 people. In addition to selling direct-to-consumer through its website, the company also has a commercial division focused on working with real estate developers, architects, designers, and construction managers.

The company also designs and engineers porcelain enamel dinnerware, bakeware, and serveware as well as handcrafted, industrial-style furniture.

When asked if more people today are searching for U.S.-made, Bryan commented that over the years, people told him he could lower costs by moving production outside the U.S.

“Yes,” he says, “I could make a lot of money going overseas. But in the long run, success is all about passion. For me, it’s all about quality. I want to be at the factory and see and touch the products being made. I want to exceed our customers’ expectations. When they receive their product from us, I want them to instantly see the difference in terms of quality and craftsmanship.

“That’s why we’ve succeeded – because this passion is infused in everything we make.”

To learn more about Barn Light Electric, visit the company website at barnlight.com